About us

“Shaping the World through thermosets and thermoplastics”

About Us

A47 MIDC Ahmednagar Plant

G11 MIDC Ahmednagar Plant

A47 MIDC Ahmednagar Plant

G11 MIDC Ahmednagar Plant

We can produce thermoset parts up to 15 kg in compression moulding and up to 2 kg in injection moulding. Thriarr Polymers processes a variety of thermoset materials, including SMC, DMC, KMC, TMC, phenolic moulding powder, U.F., melamine polyester, and more.

Our extensive portfolio includes partnerships with leading companies across industries. For the switchgear sector, we supply parts to Larsen & Toubro Ltd. for MCCB, control gear, switches, and panel boards; Siemens Ltd. for control gear parts; and Raychem RPG India for distribution boxes made of EX-grade SMC.

In the cookware industry, we provide components for Hawkins Cookers Ltd., TTK, Hosur, Nirlep Industries (Bajaj Electricals Ltd.), and Ikea India, including pressure cooker handles, knobs, and discs. Additionally, we serve the automotive sector with parts for Comstar Automobiles (solenoid caps), Visteon Automotive System, Varroc Lighting System, and Lumax Industries, supplying DMC-based components such as headlights, reflectors, and high beam parts.

With our extensive capabilities and expertise, Thriarr Polymers continues to deliver high-quality, reliable products to a wide range of industries.

Our Expertise

At Thriarr Polymers, we specialise in the manufacturing of thermoset components through a variety of moulding techniques, including compression, injection, and transfer moulding. Our modern machinery and robust engineering capabilities allow us to cater to a wide range of industries, producing high-performance parts and custom solutions. Our moulding capacity ranges from 30 tons to 530 tons of clamping force, with the ability to produce parts up to 15 kg in compression and 2 kg in injection moulding.

We work with a wide range of thermoset materials, such as SMC (Sheet Moulding Compound), DMC (Bulk Moulding Compound), KMC, TMC, phenolic moulding powder, U.F. (Urea Formaldehyde), and melamine polyester, allowing us to meet the diverse requirements of our clients.

Our Products

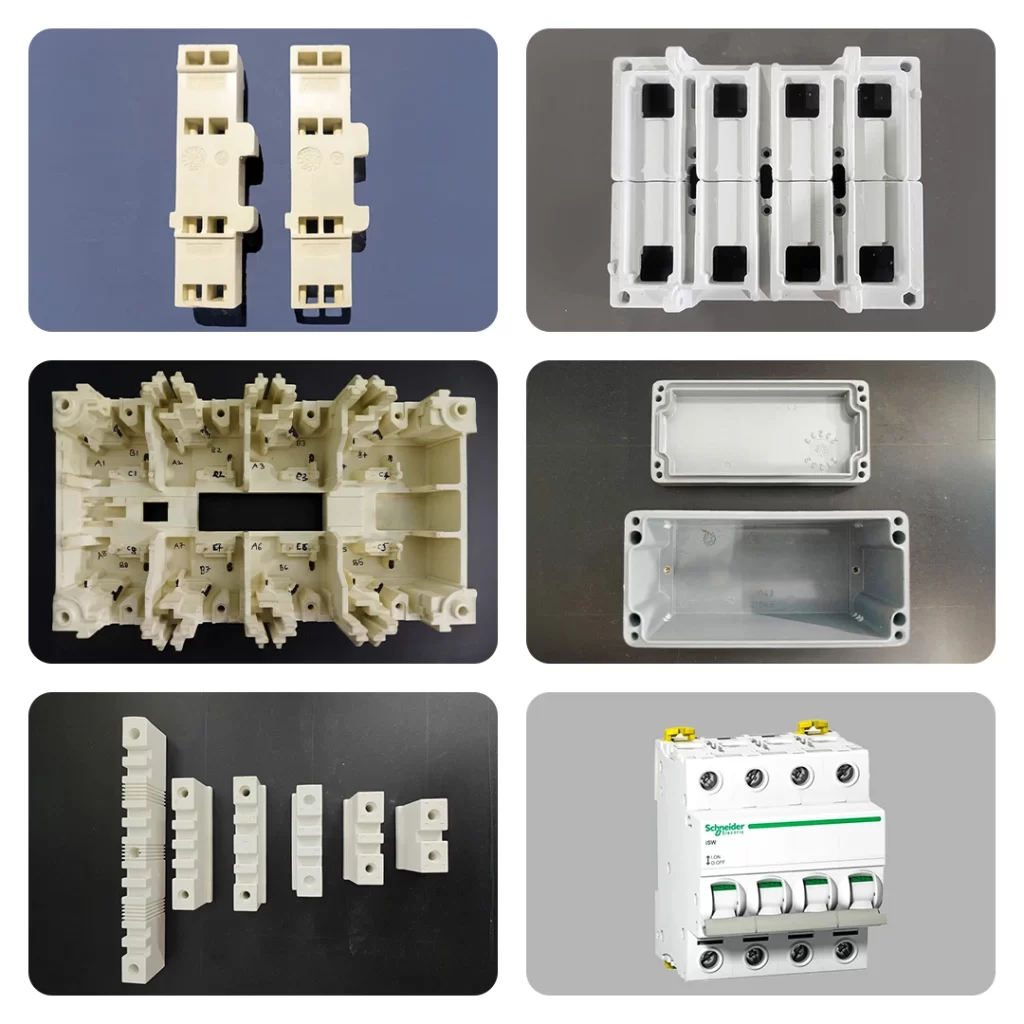

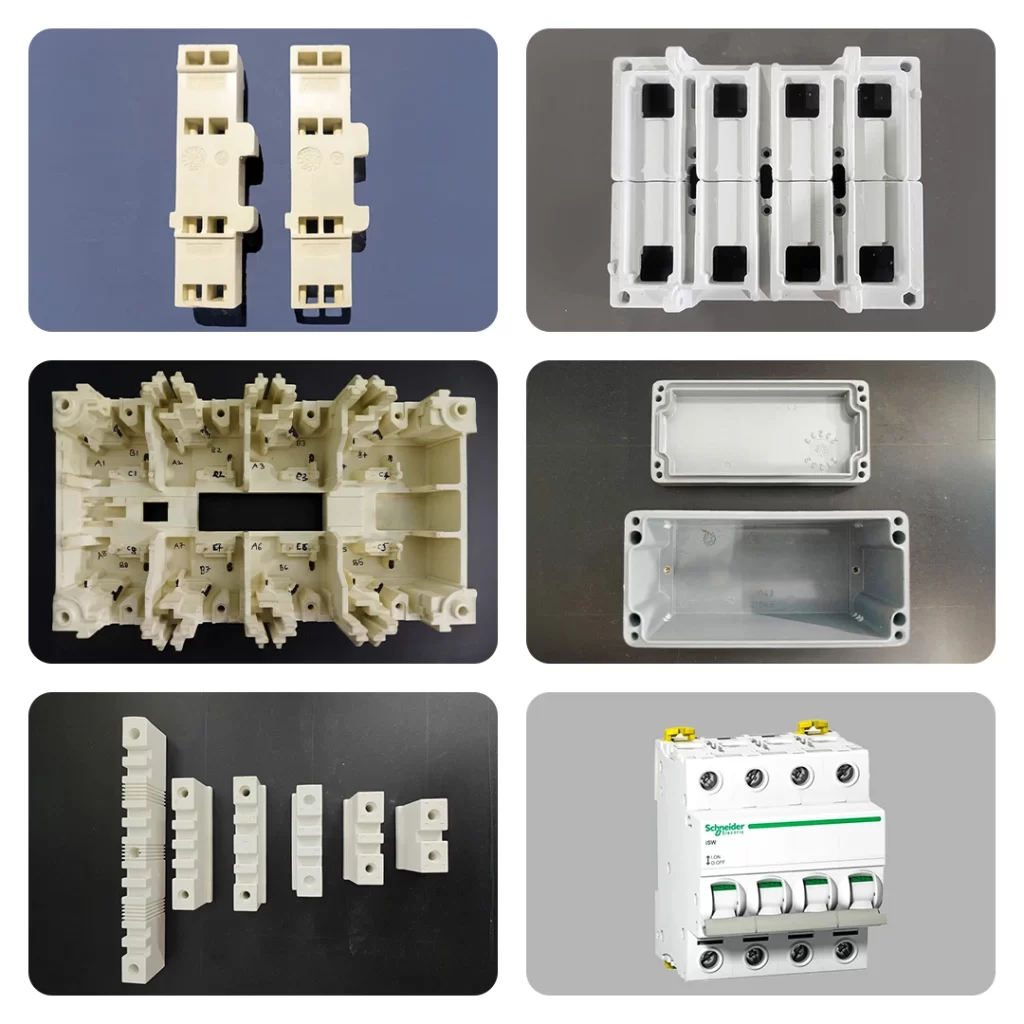

Switchgear Components:

MCCB housings, ACB components, fuse switch bodies and covers, contact carriers, and contactor housings.

Energy Meter Components:

Precision parts designed for energy metering applications.

Automobile Parts:

Components for the automotive industry, including solenoid caps, headlight reflectors, and more.

Custom Moulding Tools:

Development and manufacturing of custom moulding tools to meet specific client needs.

Core Values

Quality:

We adhere to stringent quality standards to ensure the reliability and durability of our products.

Innovation:

We embrace technological advancements to continuously improve our manufacturing processes and product offerings.

Customer Focus:

We prioritise our clients' needs, delivering tailored solutions that exceed expectations.

Integrity: We conduct our business with honesty and transparency, building trust with our stakeholders.

Our Industries Served

Thriarr Polymers has built a strong portfolio of trusted clients across various sectors:

Switchgear Industry

Serving major players like Schneider Electric Ltd., Siemens Ltd., Raychem RPG India, and Socomec with components for control gear, switches, distribution boxes, and more.

Cookware Industry

Providing products to top brands such as Hawkins Cookers Ltd., TTK, Hosur, Nirlep Industries (Bajaj Electricals Ltd.), and Ikea India, including pressure cooker handles, knobs, and discs.

Automotive Industry

Manufacturing critical components for automotive companies like Comstar Automobiles, Visteon Automotive System, Varroc Lighting System, and Lumax Industries, including solenoid caps, headlights, reflectors, and high-beam parts.

Manufacturing Facilities

We operate state-of-the-art manufacturing facilities equipped with advanced compression and injection molding machines, ranging from 30 to 530 tons clamping force. Our comprehensive capabilities enable us to produce a diverse range of products with precision and efficiency.

Quality Assurance

Quality is at the heart of everything we do at Thriarr Polymers. We are committed to providing products that meet the highest standards of durability, performance, and safety. Our adherence to ISO 9000 quality management standards ensures that every product we manufacture is thoroughly tested and meets the rigorous requirements of our clients.

We continually invest in the latest technology and maintain strict quality control measures to guarantee the reliability and precision of our products. Our quality management system is designed to meet both national and international industry standards, ensuring our products are consistently of the highest calibre.

Why Choose Thriarr Polymers?

Extensive Industry Experience

Over 40 years of expertise in the thermoset moulding industry.

State-of-the-Art Technology:

Advanced machinery with clamping forces ranging from 30 to 530 tons, capable of producing parts up to 15 kg in compression moulding and 2 kg in injection moulding.

Custom Solutions:

Ability to develop bespoke moulding tools and tailor products to meet specific client needs.

Quality Assurance:

Adherence to ISO 9000 standards, ensuring reliable and high-quality products.

Customer-Centric Approach:

A focus on delivering customer satisfaction through reliable products, on-time delivery, and personalised service.

Contact Us

For more information about our products and services or to discuss how we can help with your specific requirements, please visit our Contact Us page. We look forward to partnering with you and supporting your business with our expertise in thermoset moulded components.